Why exactly should you bother with 3D design before fabricating a custom project?

There are many answers to this question, and since I'm currently working on a custom processional cross for Jon Buell of Buell Custom Design, I can quickly point out a few things.

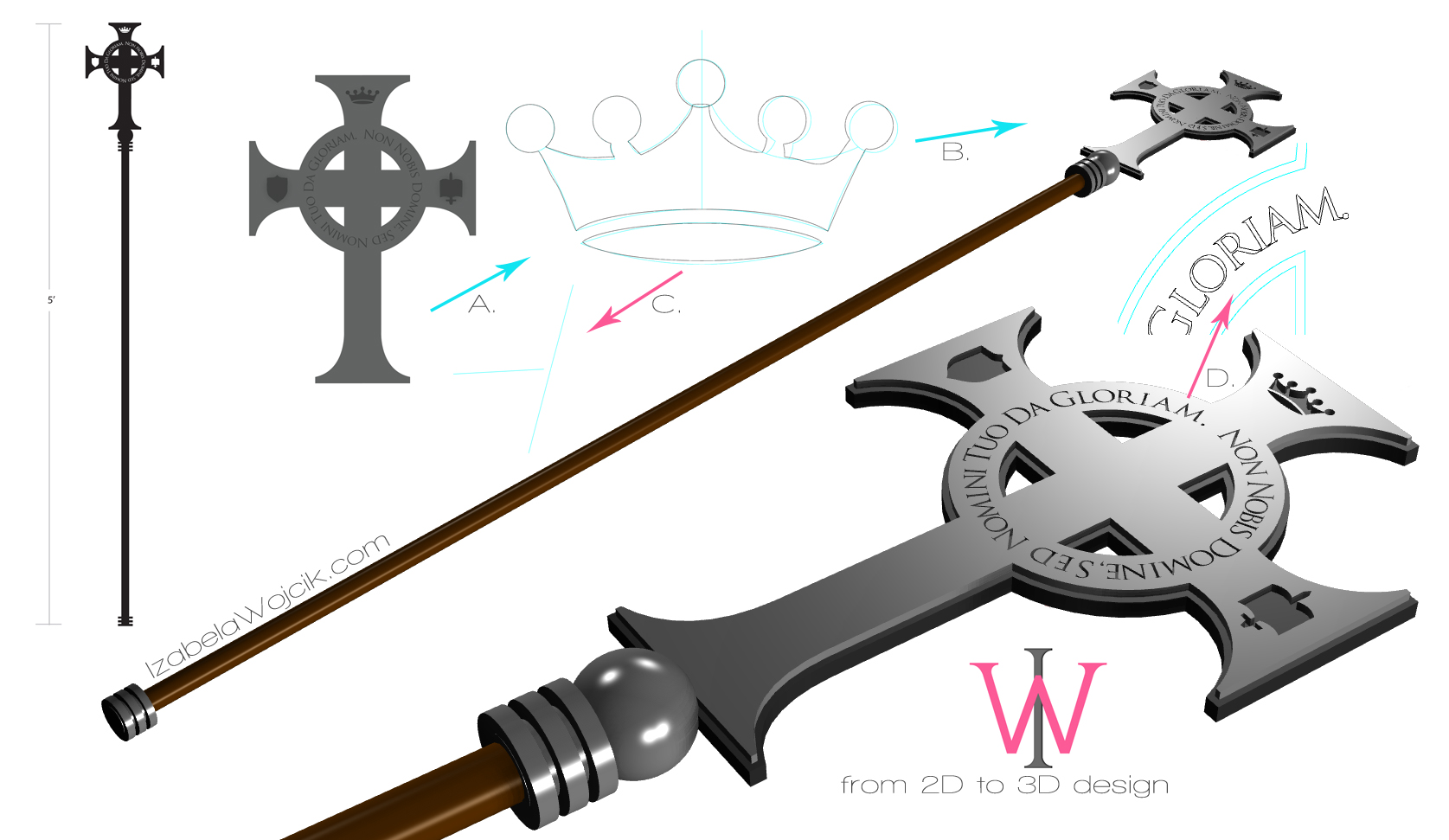

Usually I chat with a client, they tell me what they want and I put the design together, but Jon actually put together a beautiful cross design and sent it over to me. It looked fantastic! But as soon as I zoomed way in, the issues which needed to be addressed (and always do) popped up on my screen. Before I get into it, think of a great photo on your computer screen, but once you print it or try to enlarge it, all you see is a pixilated image. Well... sort of like that.

Take a look at the crown in the middle of the drawing. (click here for a larger picture) The black lines are a bit wavy (you don't notice that this happens, and it always does, unless you are working in a specialized program.) The blue lines are what I corrected and made sure that the piece is equally mirrored to both sides as well. Since this cross pieces will be initially be cut out of a metal plate by a laser or water jet cutter, the entire thing has to be programmed into the cutting machine. There are lots of people around town who do this sort of thing, but I like to work with Mike Boliver of Aquacut or Jason Brimberry of Ephesian Art; depending on what I need done. Both Mike and Jason work with an array of different programs, really work with you, and have a pretty quick turnaround time. Plus, they're absolutely lovable!

But... I'm derailing...

Another issue, and again, this happens frequently, is when two lines do not touch... like in the closeup of the blue lines. The laser or water jet cutter will run into all sorts of issues when this happens.

The third, and very important issue is that time is money! Each one of these lines has tiny little points on them. The laser is programmed to follow each line to each point. If you can get away with having one clean line, the laser will run smoothly over the entire area, and it takes less time... when the laser has to "think" about 40 points on the same line, you'll use up a whole lot of time. It's always better to clean up the images or simply start fresh and do this correctly in the first place. As you may have noticed, I did not re-design Jon's cross or the parts and pieces in it, I simply cleaned things up a bit and made them work for the machine. I also added the little step detail... if I'm going to cut two plates, I might as well use this extra detail in adding some texture to the piece. Take a look at the letters... I can tell that Jon used Illustrator to put the design together... but the problem with using this program is that once you make letters run across a circle, they will have spaces between them in some parts and, unfortunately, actually run together in other parts of the circle. I had to manually fix this problem and create spaces between each letter, or they would look a bit funny when cut out of a piece of plate.

Okay, so now that we had a little chat about line design and lasers, lets talk a bit about 3D design.

3 people can look at the cross in the upper left hand side of the drawing and imagine 3 very different ways of what the final piece will look like. This is precisely why I love designing the pieces in a 3D program, before they go into production. This way, all 3 of us will be looking at exactly what the final piece will look like, to the exact scale, with the exact dimensions, and the exact material sizes. After discussing the top drawing, we decided to handle this design in a different way. As you can see, the same design, an absolutely different cross! A little bit of work ahead of time saves a whole lot of time later on!

I can even give this cross a pretty good approximation of what the finishes will look like... that the wooden part will be oak, and the stain it will have, etc... but in this case, Jon and I already know what the finishes will look like, so the final 3D design has a more crude look to it.

At this point, I can ask Jon, "Do you like the front part of the cross being 1/8"? or would you prefer that to be a bit thinner?" It's so easy to make those decisions now, so that there are no regrets later on in the process. Changing little things in the world of custom while the piece is fabricated might not be a big deal some of the time, but other times it will hurt your pocket... preventing this is a good idea in my book!

After the two pieces return from the cutter, my guys will go to work on this cross and put the entire thing together. By doing all this ahead of time, I'm saving their time as well, and all of this translates to the piece being done correctly, as expected, and quicker than it would otherwise have. And this, of course, translates to saving time and money!

I don't need to go through these steps for every project, of course, but this one absolutely lends itself to it.

I'll be sure to thrown in a photo of the cross when it's done... you'll love it once it has all the hand worked nuances like the patina and so on worked in.